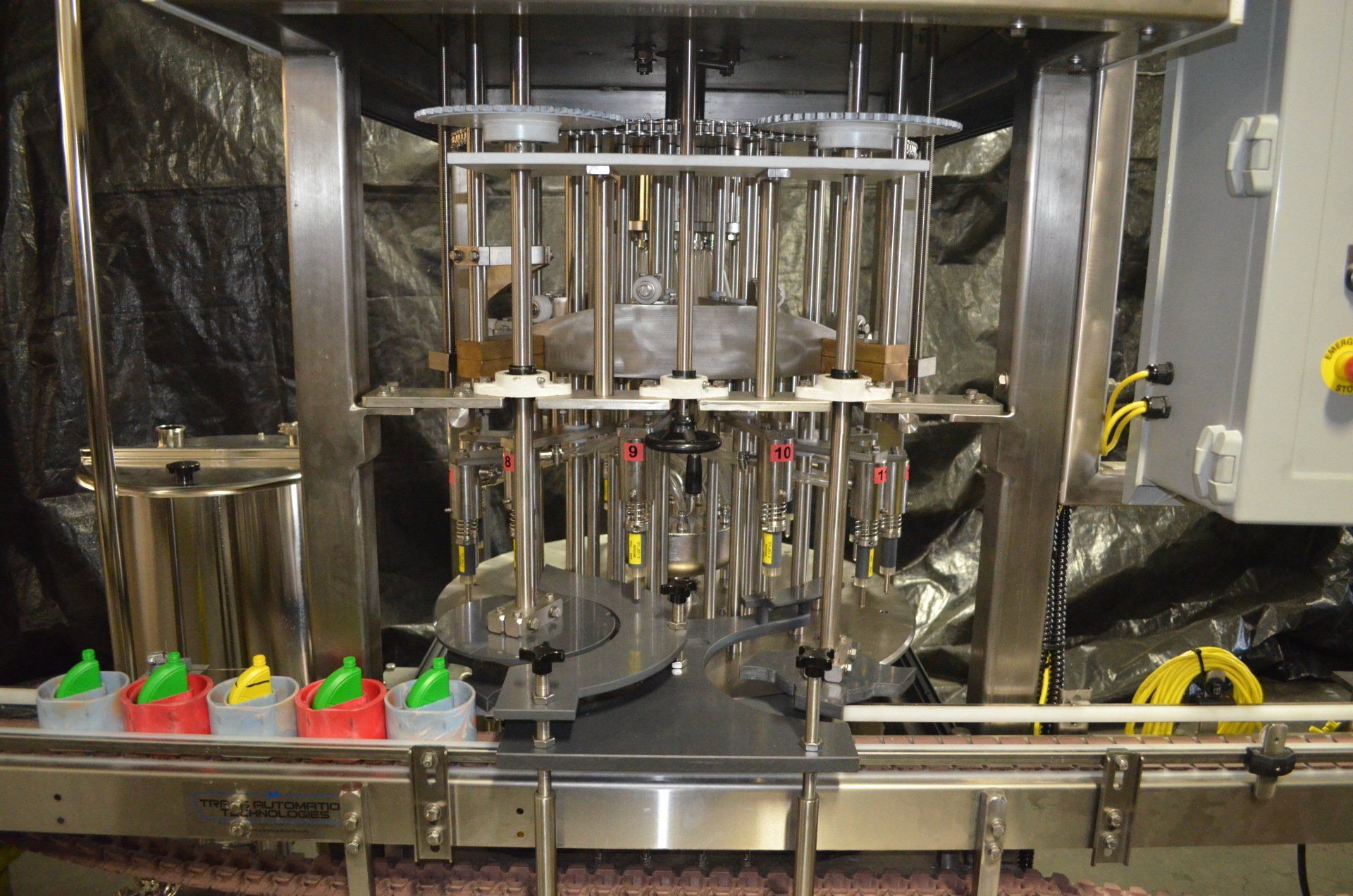

Top Benefits of Automated Bottle Filling Machines for Your Business

In today's fast-paced production environments, efficiency and precision are paramount. Automated bottle filling machines offer businesses a myriad of benefits that can significantly enhance their operational efficiency and scalability. LaubHunt.com, a leader in providing cutting-edge filling solutions, showcases a range of automated bottle filling machines designed to meet various industry needs. Here, we explore the top benefits these machines can offer to your business.

Increased Efficiency and Productivity

Automated bottle filling machines streamline the filling process, drastically reducing the time it takes to package products. Unlike manual or semi-automatic processes, these machines ensure continuous operation without fatigue or downtime. This high level of automation allows for faster production lines that can handle thousands of units per hour, dramatically increasing your output and meeting higher demand more efficiently.

Enhanced Accuracy and Consistency

Precision is crucial in the filling industry to ensure customer satisfaction and compliance with industry standards.

Automated filling machines provide exceptional accuracy in filling volumes, eliminating the variability associated with human error. This consistency ensures that each product meets quality standards, reducing waste and the need for costly reworks.

Cost-Effective Operation

While the initial investment in an automated bottle filling machine might be significant, the long-term savings are substantial. These machines reduce the labor costs associated with manual filling and the expenses incurred from errors and inconsistencies. Additionally, automated machines are designed to use resources more efficiently, such as minimizing excess product waste, which further drives down production costs.

Scalability for Business Growth

As your business grows, so does the need for scalable solutions. Automated bottle filling machines are designed to adapt to increased production needs without requiring proportional increases in labor. This scalability makes it easier for businesses to expand their operations and enter new markets without the growing pains associated with upgrading less flexible systems.

Improved Worker Safety

Automated filling machines minimize the need for direct human interaction with machinery, which significantly reduces workplace hazards. By automating the handling of bottles and the filling process, these machines lower the risk of injuries caused by repetitive motion or exposure to harmful substances.

Better Compliance with Regulations

Compliance with industry standards and regulations is easier to achieve with automated systems. These machines are built to ensure that operations adhere to health, safety, and environmental regulations. Automated systems also facilitate better record-keeping and monitoring, essential for maintaining certification and avoiding legal issues.

Enhanced Flexibility

Modern automated bottle filling machines are designed with flexibility in mind, capable of accommodating a variety of bottle sizes, shapes, and types of liquids. This versatility allows businesses to use a single machine for multiple products, reducing the need for multiple pieces of equipment and streamlining the production process. Investing in an automated bottle filling machine can transform your business operations, offering not only increased efficiency and productivity but also greater accuracy, cost savings, and scalability. Whether you’re a small startup or a large corporation, the benefits of automation are clear and compelling. Discover how Laub/Hunt's state-of-the-art filling solutions can elevate your production capabilities and help you maintain a competitive edge in your industry.

Go to LaubHunt fillers electiontoday to explore our products and find the perfect solution for your needs.