The Evolution of Bottle Filling Technology: A Historical Perspective

The world of bottle filling technology has come a long way, evolving from simple manual methods to sophisticated automated systems. At Laub/Hunt, we’re proud to be at the forefront of this evolution, providing state-of-the-art bottle filling equipment that caters to diverse industries. But before we delve into our cutting-edge products, let’s take a moment to appreciate how far we’ve come.

The Early Days: Manual Bottle Filling

In the early days, bottle filling was a labor-intensive process. Workers would manually fill bottles using basic tools like funnels and ladles. This method was not only time-consuming but also prone to spillage and contamination. Despite its inefficiencies, manual filling was the norm for small-scale operations and local businesses.

The Industrial Revolution: Mechanized Filling

The industrial revolution brought significant advancements in manufacturing, including the introduction of mechanized bottle filling equipment. These early machines were powered by steam and later electricity, allowing for faster and more consistent filling. However, they still required considerable manual oversight and maintenance.

The Rise of Automation: Electronic Bottle Filling Machines

The mid-20th century marked a turning point with the advent of electronic bottle filling machines. These machines incorporated electronic controls and sensors, significantly improving precision and efficiency. Automated systems could fill bottles at a much higher rate, reducing labor costs and increasing production capacity.

Today: Smart and Sustainable Bottle Filling Solutions

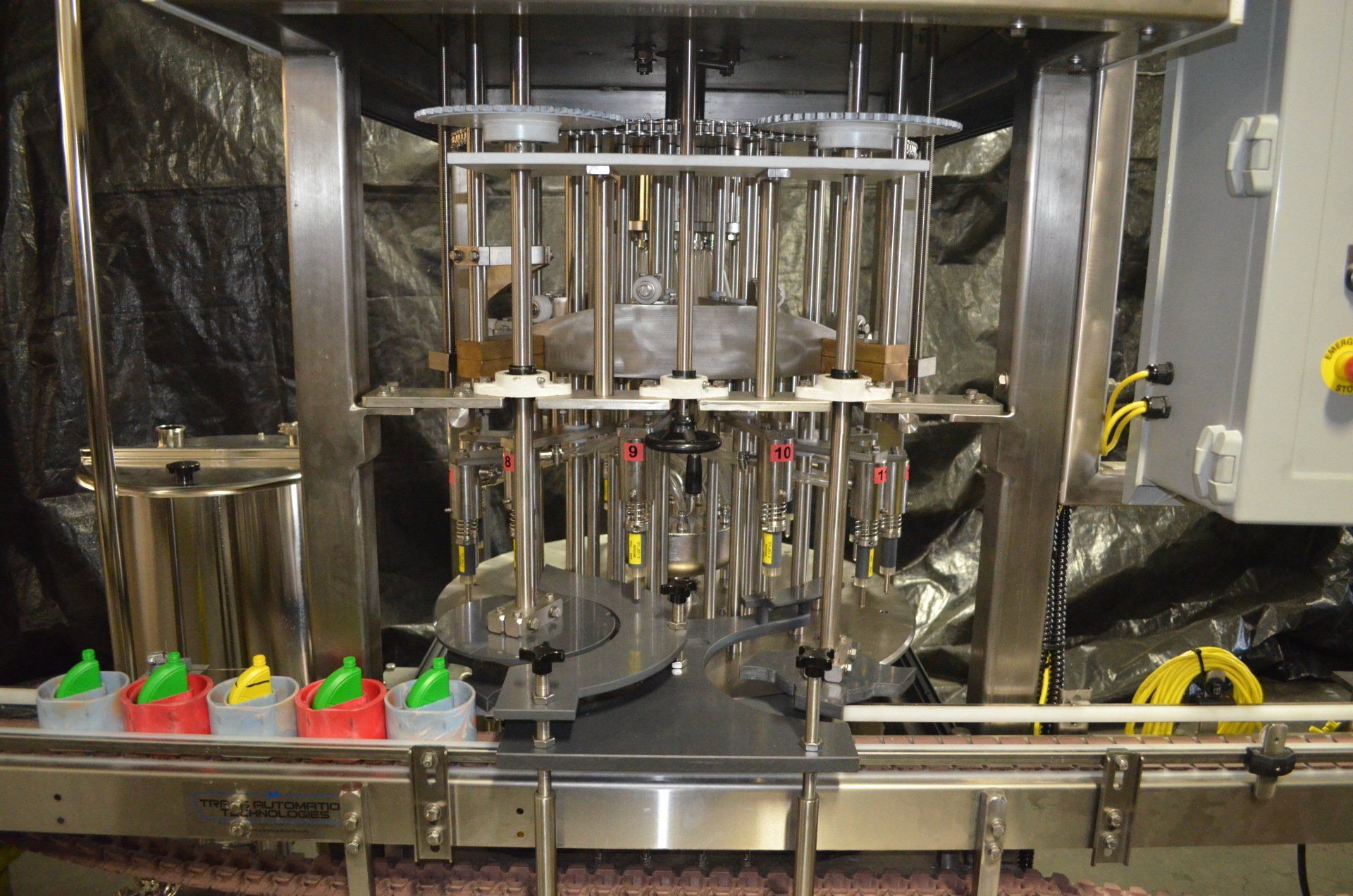

Fast forward to today, and bottle filling technology has reached new heights. At Laub/Hunt, we offer a range of advanced bottle filling equipment designed to meet the needs of modern businesses. Our machines are not only fast and accurate but also smart and sustainable.

Take, for example, our FlexiFill 3000. This versatile machine can handle various bottle sizes and types, making it ideal for businesses with diverse product lines. With its intuitive touchscreen interface and automated cleaning cycle, the FlexiFill 3000 ensures maximum efficiency and minimal downtime.

For those in the food and beverage industry, our PureFill 500 is a game-changer. This machine is designed with hygiene in mind, featuring stainless steel construction and a CIP (clean-in-place) system. The PureFill 500 guarantees that your products are filled safely and hygienically, maintaining the highest quality standards.

The Future: Innovations on the Horizon

Looking ahead, the future of bottle filling technology promises even more exciting innovations. At Laub/Hunt, we’re continuously investing in research and development to bring you the latest advancements. From AI-driven predictive maintenance to eco-friendly filling solutions, we’re committed to staying ahead of the curve.

In conclusion, the evolution of bottle filling technology is a testament to human ingenuity and progress. From humble beginnings to today’s sophisticated systems, we’ve come a long way. And with Laub/Hunt’s cutting-edge products, you can be confident that your business is equipped with the best in bottle filling technology. Stay tuned for more updates and innovations from Laub/Hunt as we continue to lead the way in this dynamic industry.