Maintaining and Troubleshooting Your Bottle Filling Machines: Expert Tips

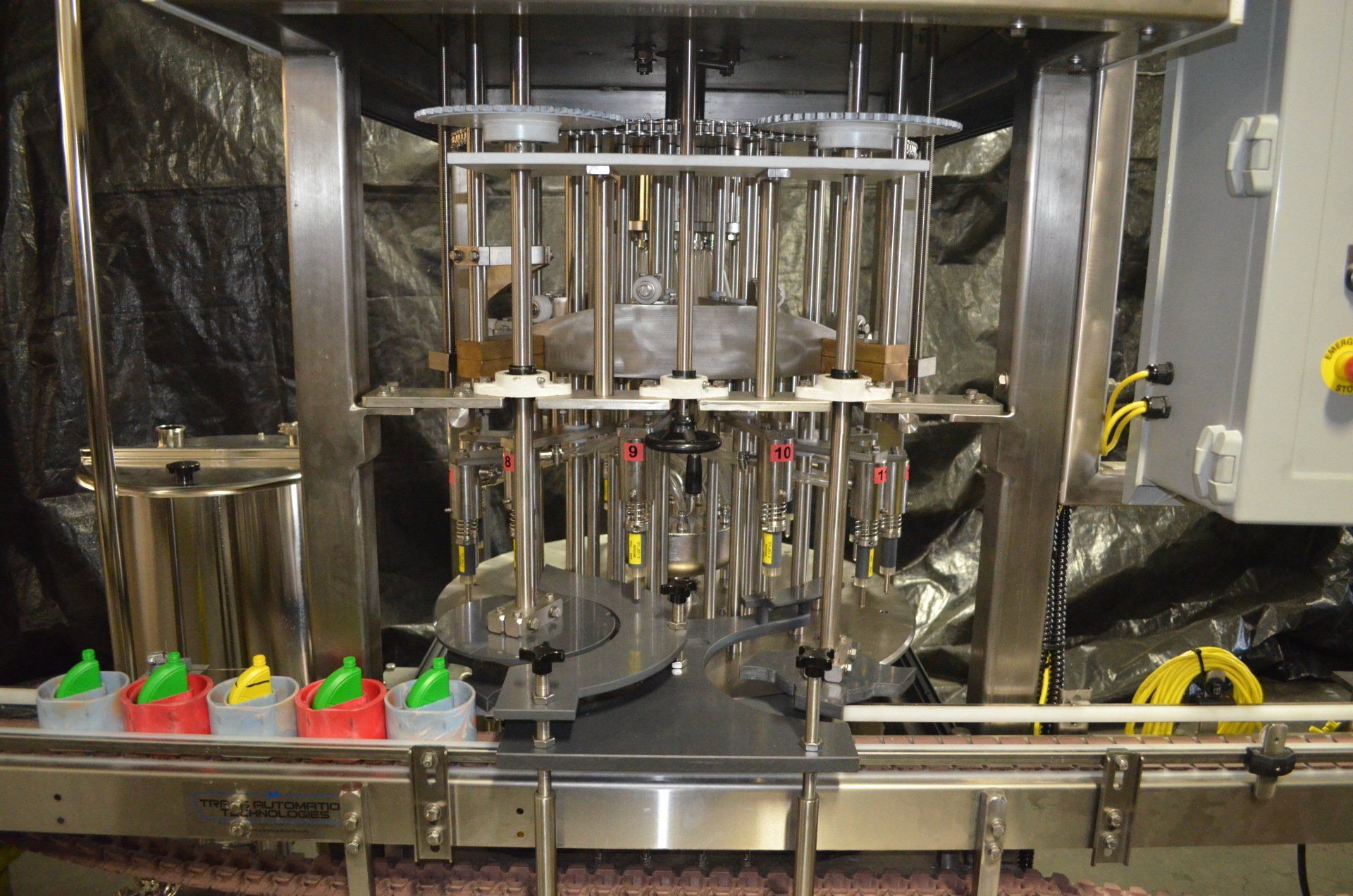

Bottle filling machines are the backbone of any bottling operation, ensuring efficiency and consistency in product packaging. However, like any machinery, they require regular maintenance and occasional troubleshooting to keep them running smoothly. Here at Laubhunt, we understand the importance of keeping your equipment in top condition. Here are expert tips to help you maintain and troubleshoot your bottle filling machines.

Regular Cleaning and Sanitation

One of the most critical aspects of maintaining your bottle filling machine is keeping it clean. Residual product and contaminants can cause blockages and affect the quality of the output. Follow these steps to ensure thorough cleaning:

- Daily Cleaning: At the end of each production day, flush the machine with clean water to remove any leftover product.

- Deep Cleaning: Schedule a more thorough cleaning weekly or bi-weekly, using food-safe cleaning agents. Disassemble parts if necessary to reach all nooks and crannies.

- Sanitation: After cleaning, sanitize all components to prevent bacterial growth, especially in food and beverage applications.

Regular Lubrication

Proper lubrication of moving parts is essential for the longevity and efficiency of your bottle filling machine. Follow the manufacturer's recommendations for lubrication intervals and use the specified lubricants to avoid any potential damage.

- Identify Key Parts: Common areas that need lubrication include gears, bearings, and seals.

- Use Quality Lubricants: Always use high-quality, manufacturer-recommended lubricants to ensure optimal performance and avoid contamination.

- Regular Checks: Conduct regular checks to ensure that lubrication points are not over or under-lubricated.

Routine Inspections

Regular inspections can help you catch potential issues before they become significant problems. Create a checklist for routine inspections, focusing on:

- Wear and Tear: Look for signs of wear on belts, seals, and other components.

- Alignment: Ensure that all parts are correctly aligned to prevent operational issues.

- Leaks: Check for any leaks in the system, which can indicate worn seals or loose fittings.

Calibrate and Adjust

Proper calibration is crucial for accurate and consistent filling. Over time, machines can drift from their set parameters, leading to inconsistent fill levels.

- Regular Calibration: Calibrate your machine regularly as per the manufacturer’s instructions.

- Adjust as Needed: Make necessary adjustments to maintain precise filling levels. Use test runs to verify the accuracy of the fill.

Troubleshooting Common Issues

Even with the best maintenance practices, problems can still arise. Here are some common issues and expert tips for troubleshooting them:

- Inconsistent Fill Levels: This can be caused by air bubbles in the product, incorrect calibration, or worn parts.

- Machine Jamming: Jamming can result from product residues, foreign objects, or misaligned components. Clean the machine thoroughly and check for obstructions.

- Leakage: Leaks can indicate worn seals or loose connections. Inspect and replace seals if necessary and tighten any loose fittings.

Training and Documentation

Ensure that all operators are adequately trained on the machine's operation and maintenance procedures. Keep detailed records of maintenance activities, calibrations, and any repairs performed.

- Training: Regularly train and update your staff on best practices for operating and maintaining the machine.

- Documentation: Maintain a log of all maintenance activities, including dates, tasks performed, and any parts replaced.

Spare Parts Inventory

Having a stock of essential spare parts can significantly reduce downtime in the event of a breakdown. Identify critical components that are prone to wear and keep them in inventory.

- Essential Parts: Common spare parts include seals, gaskets, and belts.

- Supplier Contacts: Keep contact information for reliable suppliers handy to quickly order parts when needed.

By following these expert tips, you can ensure that your bottle filling machines remain in excellent working condition, minimizing downtime and maximizing productivity. For more detailed guidance or specific issues, feel free to reach out to our team at Laubhunt. We're here to help you keep your operations running smoothly!

For more information on maintaining and troubleshooting your bottle filling machines, contact our support team. We're dedicated to providing you with the best solutions for all your bottling needs.