Integrating Bottle Filling Equipment with Packaging Lines

In today's fast-paced production environments,

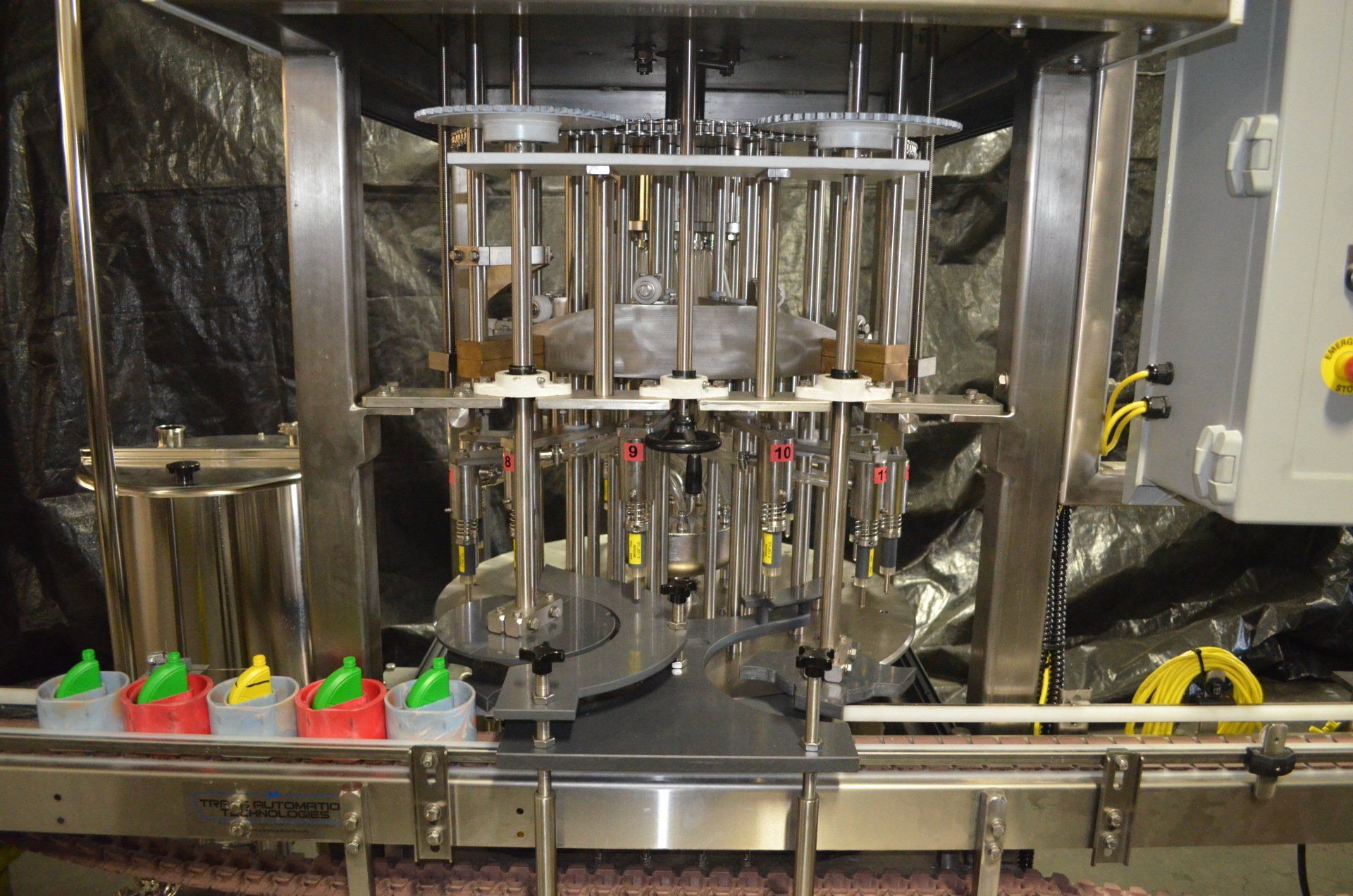

integrating bottle filling equipment with packaging lines is no longer a luxury—it’s a necessity. Seamless integration ensures smoother workflows, higher efficiency, and better product consistency across all stages of bottling and packaging.

Benefits of Integration

- Increased Efficiency: When bottle filling systems are synchronized with conveyors, cappers, labelers, and cartoners, production flows without interruption.

- Reduced Downtime: Integrated systems communicate in real time, reducing bottlenecks and minimizing manual adjustments.

- Consistent Quality: Automation maintains fill levels, eliminates spillage, and ensures uniform product presentation.

Key Considerations for Integration

- Compatibility: Equipment should be modular or customizable to adapt to varying container types, fill volumes, and production speeds.

- Control Systems: Unified control panels and PLCs streamline management and monitoring.

- Maintenance and Upkeep: Centralized systems simplify maintenance schedules and troubleshooting.

Applications Across Industries

From food and beverage to pharmaceuticals, cosmetics, and chemical manufacturing, every industry can benefit from an integrated approach. Whether you're bottling water, essential oils, or hand sanitizer, integrating equipment streamlines your entire operation.

Optimize Your Bottling Line Today

At

Laub/Hunt, we specialize in designing and supplying bottle filling equipment built for integration. Let us help you boost productivity and streamline your operations.

👉 Contact us now to discuss your filling and packaging needs.

Keywords: bottle filling equipment, packaging line integration, automated bottling systems, fill and pack solutions, production line efficiency