The Importance of Hygienic Design in Bottle Filling Equipment for Food and Beverage Industries

The Importance of Hygienic Design in Bottle Filling Equipment for Food and Beverage Industries.

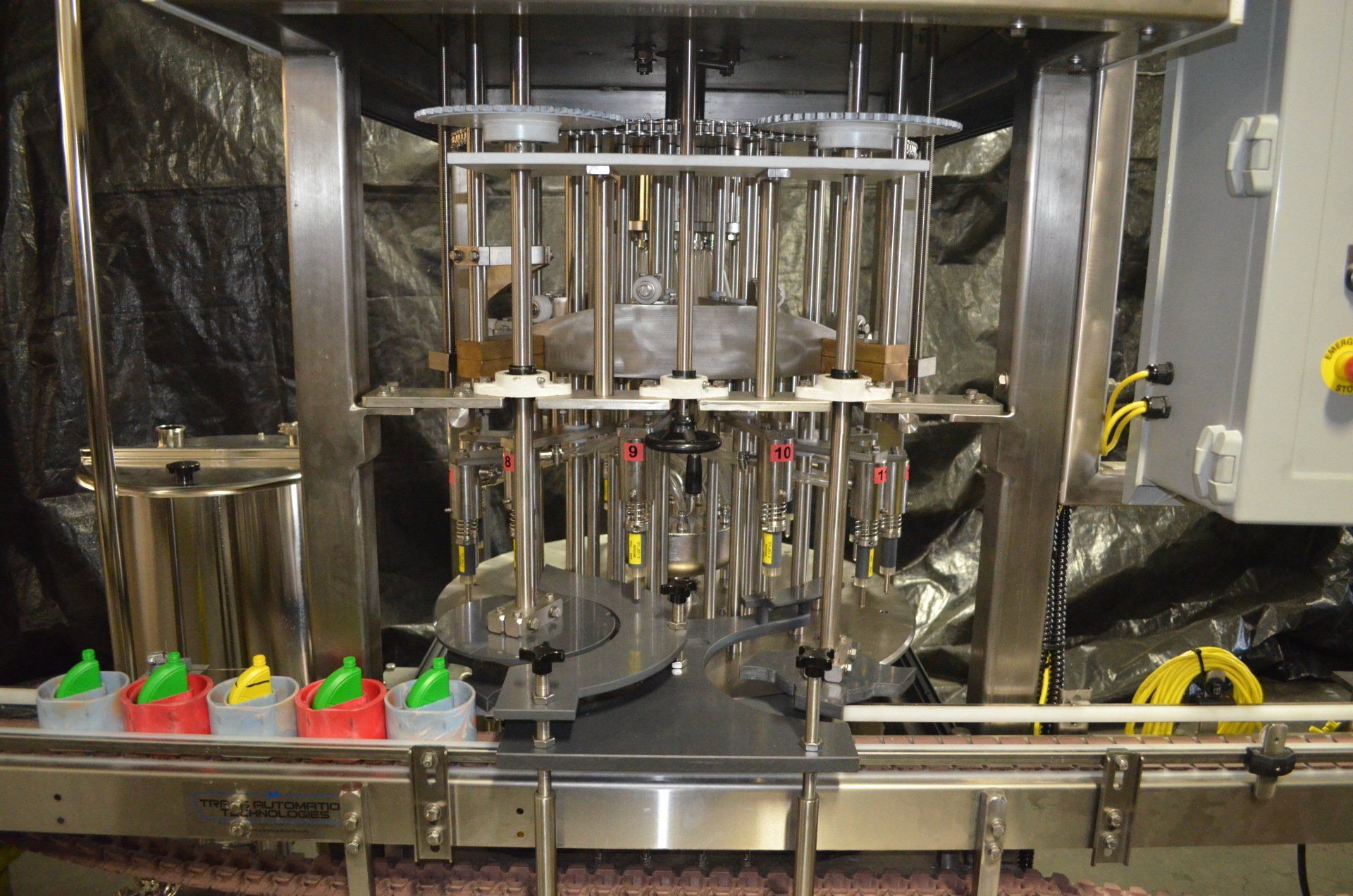

In the food and beverage industries, maintaining high levels of hygiene is not just a recommendation—it’s a necessity. One of the most critical areas where this applies is in the design of bottle filling equipment. Proper hygienic design helps prevent contamination, ensures product safety, and complies with regulatory standards. But beyond meeting these essential requirements, a focus on hygiene in equipment design can improve operational efficiency and reduce costs over time.

Why Hygienic Design Matters

In food and beverage production, every component of the process must maintain sanitary conditions. Hygienic design in bottle filling equipment means that machinery is built in a way that minimizes the risk of bacteria buildup, cross-contamination, or the growth of harmful pathogens. This involves using materials that are easy to clean, resistant to corrosion, and designed to avoid any hidden crevices where contaminants might accumulate.

A well-thought-out hygienic design also allows for efficient cleaning procedures, reducing the need for extensive downtime. By ensuring that equipment is easy to sanitize, production facilities can operate more efficiently while adhering to the strict cleanliness standards required in the industry.

Impact on Food Safety and Product Quality

One of the primary concerns in food and beverage bottling is the potential for product contamination. Contaminated products not only pose a health risk but can also lead to expensive recalls and reputational damage for companies. Hygienic design plays a vital role in safeguarding food safety by reducing the risk of contaminants entering the production line. Properly designed bottle filling equipment ensures that food and beverages are kept safe from harmful microorganisms during the filling process.

This attention to hygienic design also helps preserve the quality and integrity of the product. Consumers expect high standards from the food and beverage items they purchase, and the quality of these products begins with the equipment used to fill and package them.

Regulatory Compliance and Standards

Food safety regulations are strict, and for good reason. The FDA, USDA, and other regulatory bodies have established guidelines that manufacturers must follow to ensure the safety of food and beverage products. Bottle filling equipment that adheres to hygienic design principles makes it easier for companies to meet these regulatory requirements, reducing the risk of violations or fines.

In addition to regulatory compliance, many manufacturers also aim to achieve certifications such as ISO 22000 or HACCP (Hazard Analysis Critical Control Point) to demonstrate their commitment to food safety. A hygienic design approach in bottle filling equipment is a key factor in meeting the criteria for these certifications.

Long-Term Cost Savings and Operational Efficiency

While implementing hygienic design in bottle filling equipment may require an initial investment, the long-term benefits far outweigh the costs. Cleanable and maintainable equipment translates to fewer production stoppages for cleaning, less wear and tear on machinery, and extended equipment life. It also reduces the likelihood of product contamination, which can lead to costly recalls and damage to brand reputation.

Increased efficiency in cleaning processes, as well as fewer maintenance issues, contribute to lower operational costs and more consistent production. Hygienically designed equipment also enables facilities to operate at higher standards, minimizing the risk of non-compliance with regulatory standards.

At Laub Hunt, we understand the critical role hygienic design plays in the food and beverage industries. Our range of bottle filling equipment is designed to meet the highest hygiene standards, ensuring food safety and quality at every step. If you're looking for equipment that combines innovation with hygienic excellence, contact us today to learn more about our products and how we can help optimize your production process.