The Impact of Bottle Filling Accuracy on Product Quality and Cost

The Impact of Bottle Filling Accuracy on Product Quality and Cost

In the

beverage and pharmaceutical industries, bottle filling is a critical step in the production process. Ensuring the accuracy of bottle filling is not just about maintaining product quality; it directly affects the operational costs and overall profitability of a business. Accurate bottle filling is essential to meet regulatory standards, ensure customer satisfaction, and minimize waste, which can significantly impact both product quality and production costs.

The Importance of Bottle Filling Accuracy

Accurate bottle filling is essential to maintaining product consistency and quality. When bottles are filled to the correct level, it ensures that each unit meets the specifications promised to the customer. This is particularly important in the pharmaceutical and beverage industries, where dosage accuracy and product integrity are paramount. A consistent fill level not only upholds the quality of the product but also helps in maintaining the brand's reputation for reliability and trustworthiness.

From a regulatory standpoint, precise bottle filling is also crucial. Regulatory bodies set stringent guidelines regarding fill levels, especially in industries where the product is ingested or applied. Non-compliance with these regulations can result in costly fines, recalls, and damage to a company's reputation. By maintaining accurate filling processes, businesses can avoid these risks and ensure that their products are always in line with industry standards.

How Bottle Filling Accuracy Affects Costs

Inaccurate bottle filling can lead to significant financial losses. Overfilling bottles may seem like a minor issue, but when considered across a large production run, it can lead to substantial product loss. The cost of the excess product, multiplied by thousands or even millions of units, can quickly add up, impacting the bottom line. Additionally, overfilled bottles may require additional packaging or may not pass quality control checks, leading to increased waste and rework costs.

Underfilling, on the other hand, can lead to customer dissatisfaction and returns. Customers expect to receive the quantity they pay for, and short-filled bottles can damage the trust they have in a brand. In competitive markets, even small discrepancies can lead to loss of market share as consumers turn to competitors. Moreover, underfilled products might not meet legal requirements, leading to potential legal issues and fines.

Technologies That Enhance Bottle Filling Accuracy

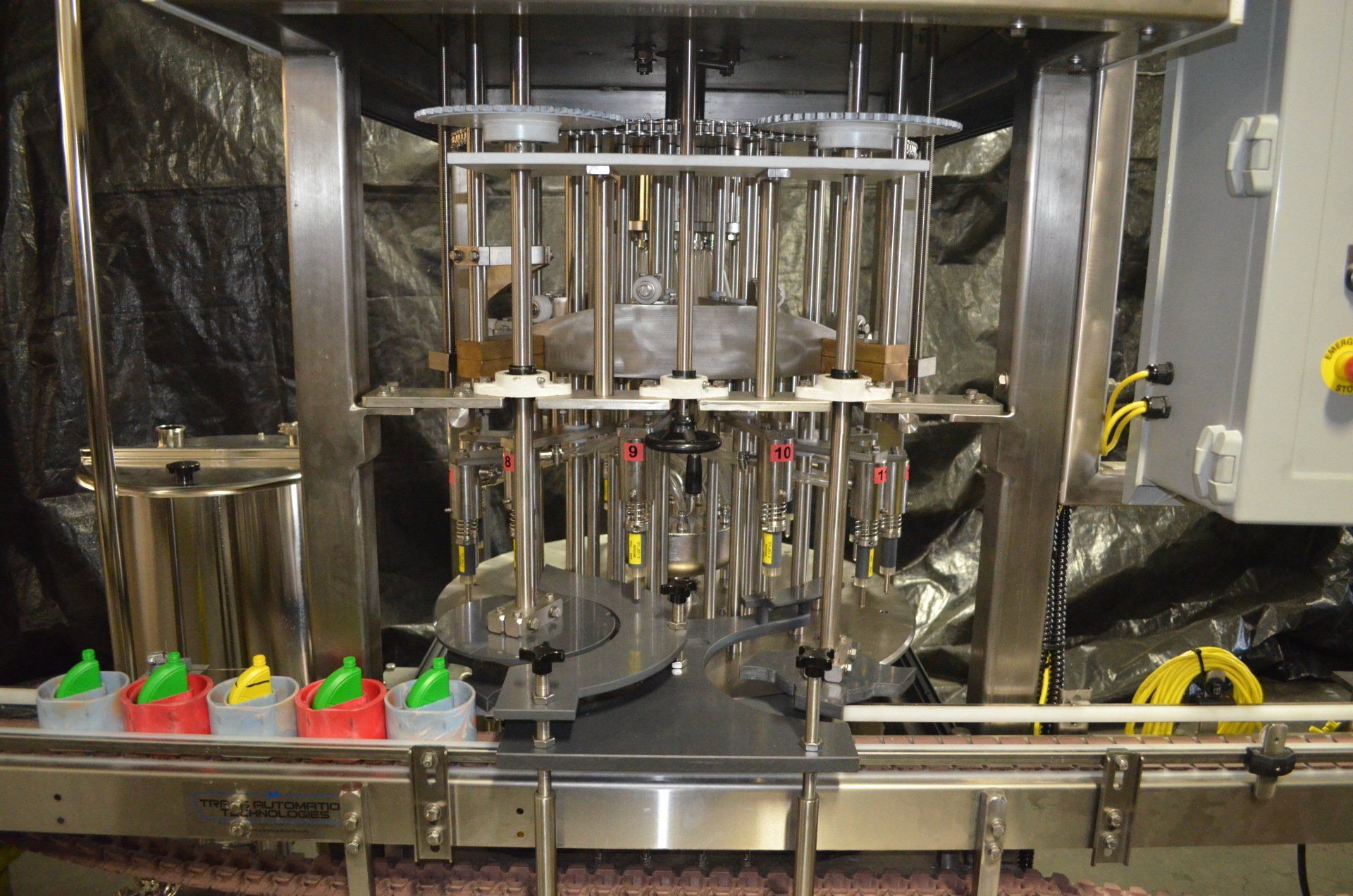

To mitigate these risks, many companies invest in

advanced bottle filling technologies that ensure precise and consistent fill levels. Modern filling machines come equipped with sensors and automated controls that adjust the fill levels in real time, compensating for variations in bottle size, temperature, and viscosity of the liquid. These technologies not only improve accuracy but also enhance the efficiency of the filling process, reducing downtime and increasing throughput.

Volumetric filling machines, for example, measure the exact volume of liquid before dispensing it into bottles, ensuring consistent fill levels regardless of external conditions. Similarly, gravimetric filling systems use weight measurements to achieve high levels of accuracy, making them ideal for products where precise dosing is critical. By choosing the right filling technology, businesses can achieve optimal accuracy, reduce waste, and enhance product quality.

The Role of Quality Control in Bottle Filling

Quality control plays a vital role in

maintaining bottle filling accuracy. Regular calibration of filling equipment, routine maintenance checks, and implementing automated inspection systems can help detect and correct inaccuracies before they result in significant production losses. Automated inspection systems, such as vision systems, can detect underfilled or overfilled bottles on the production line, allowing for immediate corrective action and minimizing the impact on overall production.

Moreover, implementing a robust quality control system helps in identifying patterns of inaccuracy that may indicate underlying equipment issues or process inefficiencies. By addressing these issues promptly, businesses can maintain high levels of filling accuracy, ensuring product quality and reducing costs associated with waste and rework.

The accuracy of bottle filling is a critical factor that influences both product quality and production costs. By investing in advanced filling technologies and maintaining rigorous quality control standards, businesses can ensure precise and consistent filling levels. This not only enhances product quality and customer satisfaction but also minimizes waste and reduces costs, contributing to overall profitability. In today’s competitive market, achieving accurate bottle filling is not just an operational necessity but a strategic advantage that can set a brand apart from its competitors. Contact us for more information.