Customizing Bottle Filling Machines for Unique Product Needs

When it comes to bottle filling equipment, one size certainly does not fit all. Every product has its own unique requirements, and off-the-shelf machinery might not meet the specific demands of your production line. Customizing your bottle filling machines allows for greater flexibility, ensuring your products are filled with precision and efficiency, no matter their viscosity, temperature, or packaging style.

At Laub Hunt, we understand the complexities of handling different types of liquids and products. From thick sauces to delicate beverages, each product requires careful consideration in terms of filling speed, accuracy, and container compatibility. With customization, we can ensure your bottle filling machine is tailored specifically to your product's needs.

Why Customization Matters

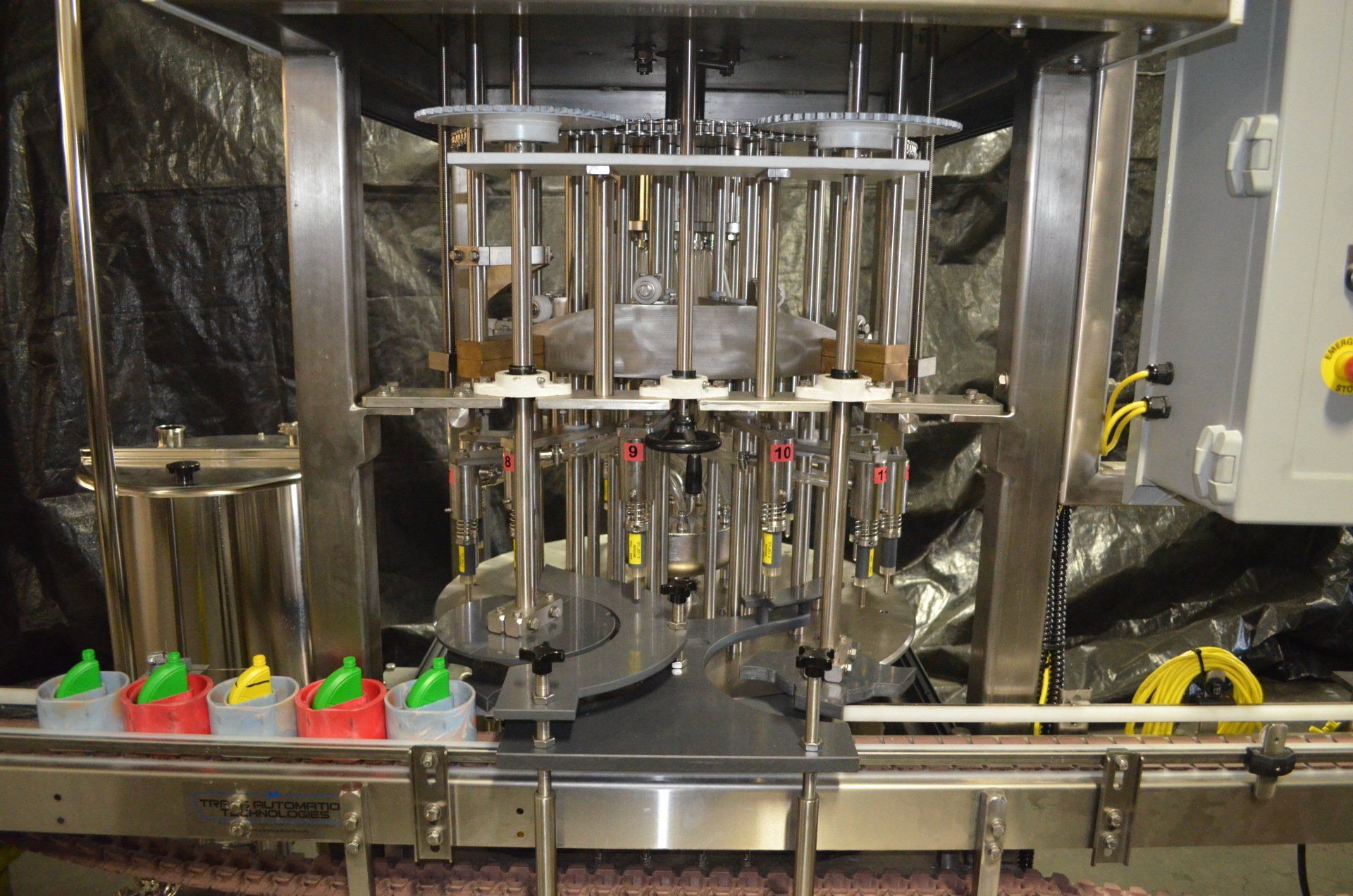

Each product has its own set of challenges. For instance, filling machines designed for thin, free-flowing liquids may struggle with thicker substances, leading to inconsistent fills or product wastage. Customizing your machine ensures that it’s engineered to handle the specific characteristics of your product—whether that’s a high viscosity liquid, a product that requires temperature control, or even a foamy beverage that needs gentle handling. A tailored solution allows your production line to operate smoothly. This customization can include adjusting the machine’s nozzles, integrating specialized sensors to maintain consistent fill levels, or modifying the conveyor system to accommodate unique bottle shapes and sizes.

When it comes to bottle filling equipment, one size certainly does not fit all. Every product has its own unique requirements, and off-the-shelf machinery might not meet the specific demands of your production line. Customizing your bottle filling machines allows for greater flexibility, ensuring your products are filled with precision and efficiency, no matter their viscosity, temperature, or packaging style.

At Laub Hunt, we understand the complexities of handling different types of liquids and products. From thick sauces to delicate beverages, each product requires careful consideration in terms of filling speed, accuracy, and container compatibility. With customization, we can ensure your bottle filling machine is tailored specifically to your product's needs.

Why Customization Matters

Each product has its own set of challenges. For instance, filling machines designed for thin, free-flowing liquids may struggle with thicker substances, leading to inconsistent fills or product wastage. Customizing your machine ensures that it’s engineered to handle the specific characteristics of your product—whether that’s a high viscosity liquid, a product that requires temperature control, or even a foamy beverage that needs gentle handling.

A tailored solution allows your production line to operate smoothly. This customization can include adjusting the machine’s nozzles, integrating specialized sensors to maintain consistent fill levels, or modifying the conveyor system to accommodate unique bottle shapes and sizes.

Addressing Industry Regulations

Customization isn’t just about improving production efficiency; it’s also about meeting industry standards and regulations. Food and beverage industries, in particular, have strict hygiene and safety standards that require specific design features. Customizing your bottle filling equipment to meet these requirements ensures your production line remains compliant, reducing the risk of contamination or costly fines.

Our team at Laub Hunt has extensive experience in developing solutions that are not only functional but meet the necessary regulatory standards. We offer customization options that incorporate sanitary designs, CIP (Clean-in-Place) systems, and other features critical for industries with strict hygiene requirements.

Flexibility for Future Growth

One of the significant benefits of customizing your bottle filling machines is scalability. As your product line grows or diversifies, you need equipment that can keep up. By customizing your filling machines today, you’ll have the flexibility to adapt to future changes—whether you’re introducing a new product or expanding your production capacity.

Customized machines offer modularity, meaning you can upgrade or tweak the system as needed without investing in an entirely new setup. This flexibility is crucial in today’s fast-paced market, where the ability to pivot quickly can set you apart from competitors.

The Laub Hunt Advantage

At Laub Hunt, we specialize in designing bottle filling machines that meet the unique needs of our clients. Whether you’re filling small bottles with pharmaceuticals or large containers with cleaning chemicals, we’ll work with you to create a solution that enhances both efficiency and product quality. Our engineers collaborate closely with your team to understand your product specifications, production goals, and any regulatory constraints you may face.

We don’t believe in a “one-size-fits-all” approach—each project is treated as unique, and our solutions are designed with your specific needs in mind. This level of customization helps ensure optimal performance and longevity of your equipment, reducing downtime and increasing throughput.

Let’s Get Started

If you’re looking for a bottle filling machine designed to meet the unique requirements of your product, Laub Hunt is here to help. Our team of experts is ready to collaborate with you on designing a customized solution that will streamline your production process and keep you ahead of industry trends. Contact us today to discuss your project and learn how we can make your filling equipment work smarter for your business.

Ready to customize your bottle filling machine? Contact Laub Hunt today and let’s get started on building the perfect solution for your unique production needs!

4o

Customization isn’t just about improving production efficiency; it’s also about meeting industry standards and regulations. Food and beverage industries, in particular, have strict hygiene and safety standards that require specific design features. Customizing your bottle filling equipment to meet these requirements ensures your production line remains compliant, reducing the risk of contamination or costly fines.

Our team at Laub Hunt has extensive experience in developing solutions that are not only functional but meet the necessary regulatory standards. We offer customization options that incorporate sanitary designs, CIP (Clean-in-Place) systems, and other features critical for industries with strict hygiene requirements.

Flexibility for Future Growth

One of the significant benefits of customizing your bottle filling machines is scalability. As your product line grows or diversifies, you need equipment that can keep up. By customizing your filling machines today, you’ll have the flexibility to adapt to future changes—whether you’re introducing a new product or expanding your production capacity.

Customized machines offer modularity, meaning you can upgrade or tweak the system as needed without investing in an entirely new setup. This flexibility is crucial in today’s fast-paced market, where the ability to pivot quickly can set you apart from competitors.

The Laub Hunt Advantage

At Laub Hunt, we specialize in designing bottle filling machines that meet the unique needs of our clients. Whether you’re filling small bottles with pharmaceuticals or large containers with cleaning chemicals, we’ll work with you to create a solution that enhances both efficiency and product quality. Our engineers collaborate closely with your team to understand your product specifications, production goals, and any regulatory constraints you may face.

We don’t believe in a “one-size-fits-all” approach—each project is treated as unique, and our solutions are designed with your specific needs in mind. This level of customization helps ensure optimal performance and longevity of your equipment, reducing downtime and increasing throughput.

Let’s Get Started

If you’re looking for a bottle filling machine designed to meet the unique requirements of your product, Laub Hunt is here to help. Our team of experts is ready to collaborate with you on designing a customized solution that will streamline your production process and keep you ahead of industry trends. Contact us today to discuss your project and learn how we can make your filling equipment work smarter for your business.