The Role of Bottle Filling Equipment in Beverage Industry Growth

The beverage industry is an ever-evolving sector, driven by consumer demands for convenience, variety, and quality. From carbonated drinks to juices, bottled water, and alcoholic beverages, the market's expansion has been fueled by innovations in production processes, packaging, and most importantly, bottle filling equipment. This blog explores the pivotal role bottle filling equipment plays in the growth and success of the beverage industry.

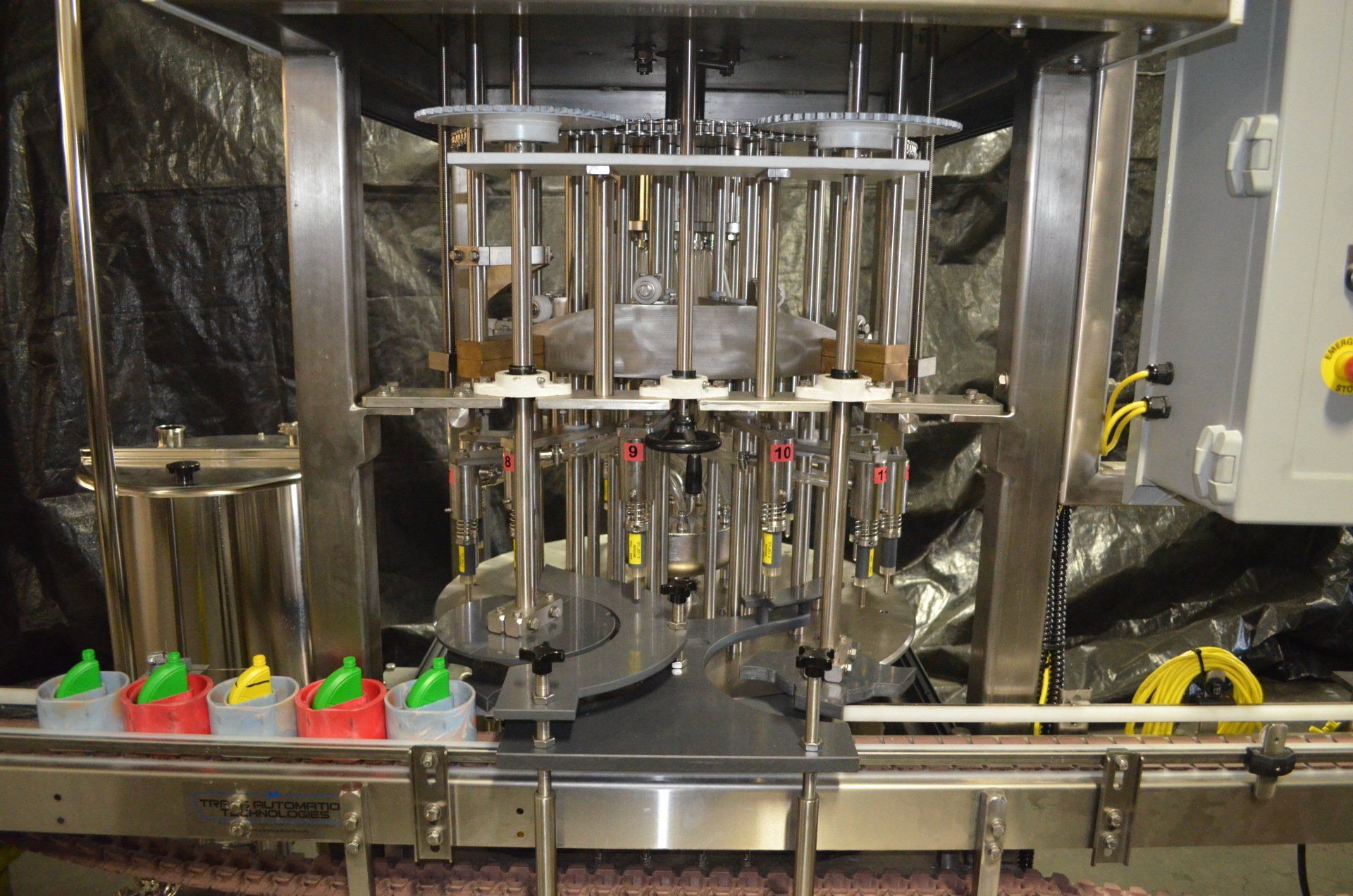

Efficiency and Speed

The beverage industry thrives on high production volumes. Bottle filling equipment is designed to meet this demand, offering efficient and speedy operations that ensure beverages are filled, sealed, and ready for distribution in record time. High-speed filling machines can process thousands of bottles per hour, making them essential for meeting the production needs of large beverage companies. This efficiency not only helps companies meet consumer demands but also reduces production costs, contributing to overall profitability.

Consistency and Quality Control

Consistency is key in the beverage industry. Consumers expect their favorite drinks to taste the same every time they purchase them. Bottle filling equipment ensures uniformity in every bottle by accurately measuring and dispensing liquids. Advanced machines are equipped with precision sensors and automated controls that minimize human error, ensuring that each bottle is filled with the exact amount of beverage. This consistency is crucial for maintaining brand reputation and customer loyalty.

Flexibility and Adaptability

The beverage market is diverse, with products ranging from still water to carbonated drinks, energy drinks, and alcoholic beverages. Bottle filling equipment must be versatile enough to handle different types of liquids, viscosities, and packaging sizes. Modern filling machines are highly adaptable, allowing manufacturers to switch between products with minimal downtime. This flexibility is essential for companies looking to diversify their product lines and stay competitive in a dynamic market.

Hygiene and Safety

Hygiene is a top priority in the beverage industry. Bottle filling equipment is designed to meet stringent hygiene standards, ensuring that products are safe for consumption. Machines are made from food-grade materials and are often equipped with automated cleaning systems that prevent contamination. By maintaining a sterile production environment, manufacturers can protect consumers from health risks and avoid costly product recalls.

Sustainability and Environmental Impact

Sustainability is becoming increasingly important in the beverage industry.

Bottle filling equipment plays a significant role in reducing environmental impact by minimizing waste and optimizing resource use. For example, modern filling machines are designed to reduce water and energy consumption during the production process. Additionally, they are compatible with eco-friendly packaging options, such as lightweight bottles and recyclable materials, helping companies meet their sustainability goals.

Supporting Innovation and New Product Development

Innovation is the lifeblood of the beverage industry. Bottle filling equipment supports the development of new products by allowing manufacturers to experiment with different formulations and packaging options. Whether it's introducing a new flavor, a healthier beverage option, or a limited-edition product, advanced filling machines provide the flexibility and precision needed to bring innovative ideas to market quickly and efficiently.

The growth of the beverage industry is closely tied to advancements in bottle filling equipment. As consumer demands continue to evolve, manufacturers rely on these machines to deliver high-quality products efficiently and sustainably. From ensuring consistency and quality control to supporting innovation and sustainability efforts, bottle filling equipment is an indispensable part of the beverage industry's success. By investing in state-of-the-art filling technology, companies can stay ahead of the competition, meet consumer expectations, and contribute to the industry's continued growth.

At Laubhunt.com, we understand the importance of reliable and efficient bottle filling equipment in driving your business forward. Explore our range of cutting-edge solutions designed to meet the diverse needs of the beverage industry. Contact us today to learn how we can help you achieve your production goals and support your growth in this dynamic market. Contact us fore more information.