Choose the Right Bottle Filling Equipment for Your Production Line

Choosing the right bottle filling equipment is crucial for optimizing the efficiency and productivity of your production line. With a variety of options available, it can be challenging to determine which type best suits your specific needs. Here are key factors to consider when selecting bottle filling equipment for your production line.

Understanding Your Product

The first step in choosing the right bottle filling equipment is understanding your product. Different products have varying viscosity, foaming characteristics, and particulate content, which influence the type of filling machine required. For example:

- Liquid Products: For water, juices, and other thin liquids, gravity fillers are typically suitable.

- Viscous Products: Thicker products like sauces, creams, and gels require piston fillers.

- Foamy Products: Carbonated beverages and other foamy liquids are best handled with counter-pressure fillers.

Production Volume and Speed

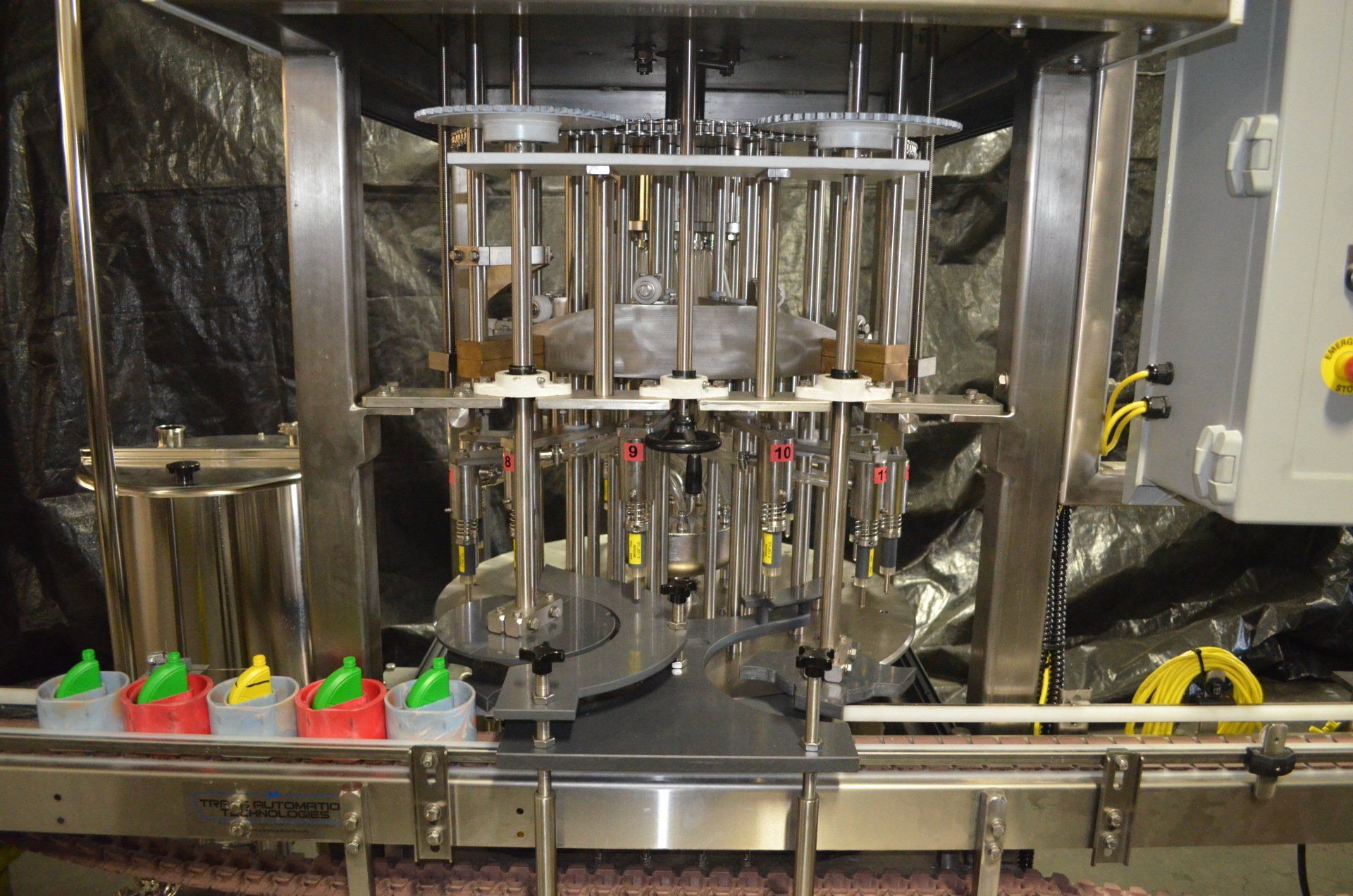

Your production volume and the desired speed of your filling line play a significant role in determining the right equipment. High-speed rotary fillers are ideal for large-scale operations, while inline fillers are better suited for small to medium-sized production runs. Assess your production goals and choose equipment that can meet your capacity requirements without compromising on quality.

Type of Containers

Consider the types of containers you will be using. Bottle filling equipment must be compatible with the size, shape, and material of your bottles. Whether you're filling glass bottles, plastic containers, or cans, ensure the equipment can handle the specific dimensions and design of your containers to avoid spillage and ensure a secure seal.

Filling Accuracy and Precision

Accuracy and precision are critical in bottle filling operations to maintain product consistency and avoid wastage. Advanced filling machines come with features like automated controls and sensors that ensure precise filling volumes. Look for equipment with adjustable settings to accommodate different fill levels and minimize variations.

Cleanliness and Maintenance

Hygiene is paramount, especially for food and beverage products. Choose filling equipment that is easy to clean and maintain to prevent contamination. Stainless steel construction, CIP (Clean-in-Place) systems, and easy access to parts for cleaning are essential features to look for in bottle filling machines.

Budget and Cost of Ownership

While it's important to stay within your budget, consider the long-term cost of ownership, including maintenance, repairs, and energy consumption. Investing in high-quality, durable equipment may have a higher upfront cost but can save you money in the long run through reduced downtime and extended lifespan.

Customization and Flexibility

Your production needs may evolve over time, so selecting versatile and customizable equipment is a wise decision. Look for machines that offer flexibility in terms of filling volumes, container sizes, and production rates. This adaptability can help future-proof your investment and allow you to scale your operations as needed.

Choosing the right bottle filling equipment is a critical decision that impacts the efficiency, quality, and profitability of your production line. By understanding your product, production volume, container type, and other key factors, you can select equipment that meets your specific needs. For a comprehensive range of bottle filling equipment and expert guidance, visit Laubhunt.com today. Our team is dedicated to helping you find the perfect solution for your production line.