Comparing Manual vs. Automated Bottle Filling: Which is Best for Your Company?

When it comes to bottle filling, businesses face a crucial decision — manual or automated bottle filling? Each method offers unique benefits and drawbacks, depending on production needs, business goals, and budget. Understanding the differences can help you choose the right option to optimize efficiency, reduce costs, and maintain product quality.

What is Manual Bottle Filling?

Manual bottle filling requires human operators to fill, cap, and label bottles. While it typically involves using simple machinery or hand-operated tools, it is slower and more labor-intensive compared to automation. Key features of manual bottle filling include reliance on human labor, greater flexibility for different bottle sizes, and lower initial costs. The benefits of manual bottle filling include cost-effectiveness for small batches, greater control over the process, and a simple setup with minimal training required. However, it comes with challenges such as increased labor costs, inconsistent fill levels due to human error, and limited scalability for large production runs.

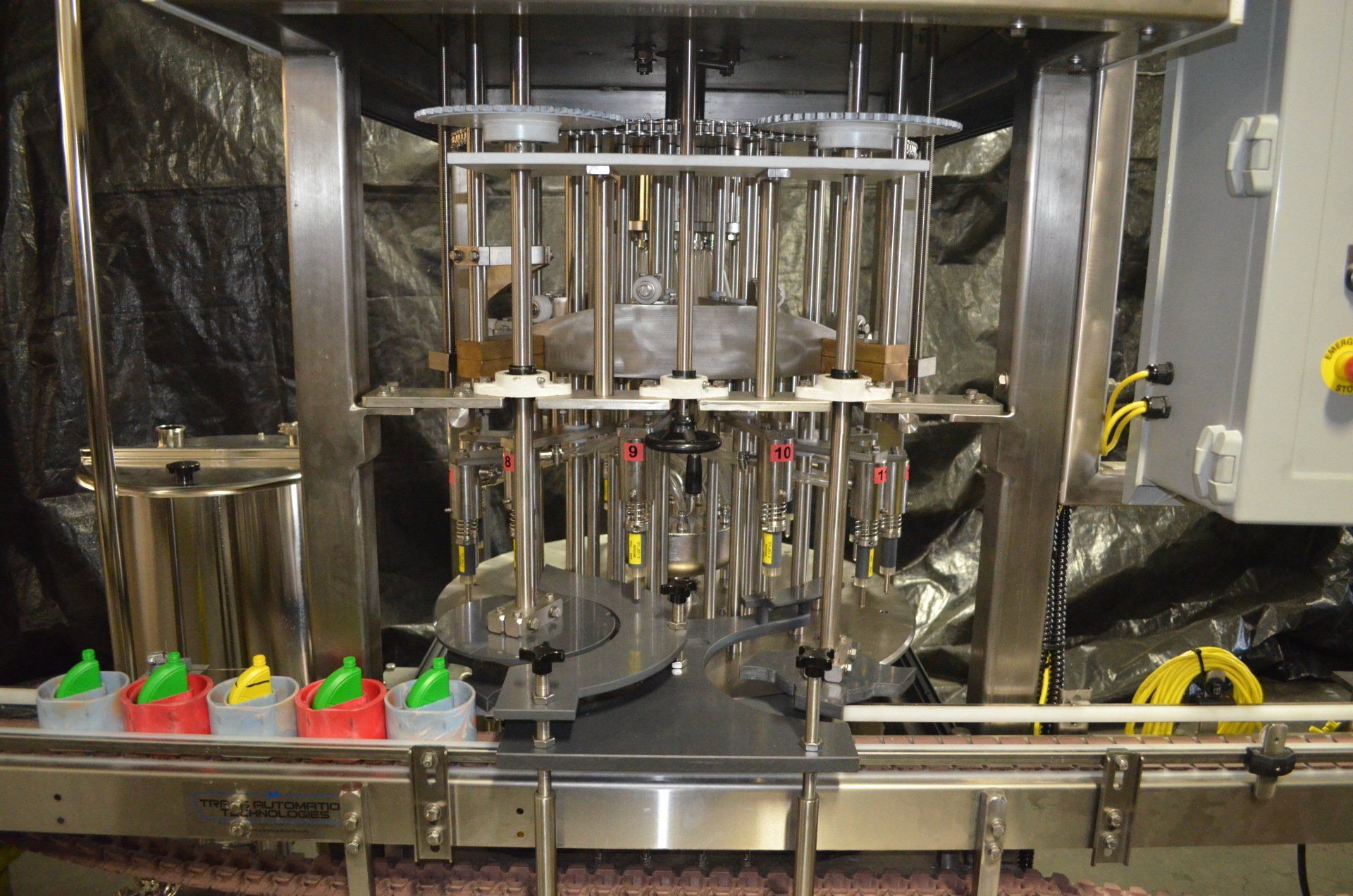

What is Automated Bottle Filling?

Automated bottle filling uses advanced machinery to fill bottles quickly, accurately, and with minimal human intervention. This system is popular in industries where speed and precision are essential, such as food and beverage, cosmetics, pharmaceuticals, and chemicals. Automated bottle filling features high-speed production, consistent fill levels, and customization options for different bottle sizes. The benefits of automated bottle filling include increased production efficiency, lower labor costs, precision and accuracy, and access to production data and analytics. However, automation also has challenges, such as high initial investment, ongoing maintenance needs, and the requirement for technical training to operate the equipment.

Key Differences Between Manual and Automated Bottle Filling

Manual bottle filling is more affordable upfront but requires more human labor, while automated filling requires a higher initial investment but reduces labor costs in the long term. Manual filling is best for small batches and customized orders, while automation excels at high-speed, large-volume production. Automated systems ensure consistent and accurate fills, while manual filling is prone to human error. When it comes to flexibility, manual systems can quickly adapt to new bottle sizes, while automated systems may require reconfiguration. If you’re looking for scalability, automation offers a clear advantage, as it can handle larger production volumes with ease.

Which Bottle Filling Method is Best for Your Business?

The choice between manual and automated bottle filling depends on your production needs and goals. Manual bottle filling is best for small businesses, startups, and companies with limited production volumes. It’s also a great option if you prioritize cost savings and flexibility. On the other hand, automated bottle filling is ideal for businesses with high production volumes, growth potential, and a need for precision and efficiency. Companies in food, cosmetics, and pharmaceutical industries often benefit from automated filling due to the strict quality standards they must meet.

Future-Proof Your Business with Hybrid Solutions

If a full transition to automation seems out of reach, consider a hybrid solution. Semi-automated systems allow operators to handle certain steps while machines manage others, offering a balance of cost savings and efficiency. This approach can be a smart step toward future-proofing your production line.

Need Help Choosing the Right Bottle Filling Solution?

At Laub/Hunt, we provide customized bottle filling equipment designed to meet the unique needs of your industry. Our team of experts can guide you through the decision-making process, helping you choose the best solution — whether it’s manual, automated, or a hybrid system.

Ready to increase production efficiency and reduce costs?

Contact Laub/Hunt today to learn more about our bottle filling solutions. Our experienced team is ready to help you select the best system for your production needs. Call us or request a consultation on our website.

Upgrade Your Production Process with Laub/Hunt — Your Trusted Bottle Filling Partner.