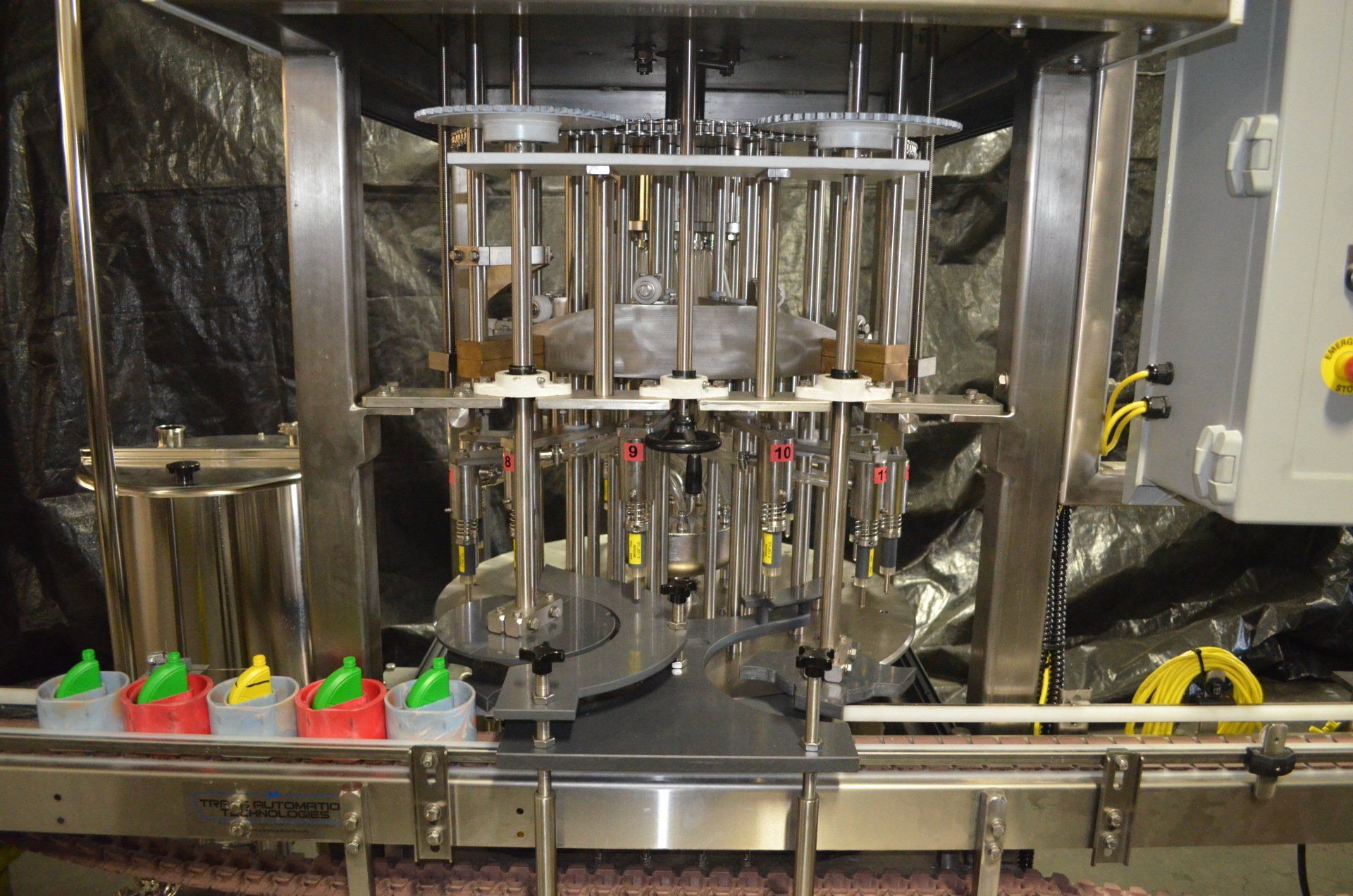

Comprehensive Engineering Services from LAUB\HUNT: Your Global Partner in Liquid Filling Equipment Solutions

At Laub\Hunt, we specialize in delivering innovative engineering solutions for liquid filling equipment and production lines. With a global reputation for reliability and precision, we offer services that ensure your operations run efficiently and effectively. From turn-key project management to technical support and field services, our team is here to support your machinery needs at every stage of the process.

Expertise in Liquid Filling Equipment Solutions

LAUB\HUNT is your trusted partner for complete production line integration. Whether you're starting a new project or upgrading existing equipment, we offer a wide range of services tailored to meet your specific requirements:

- Engineering for Line Integration: Our team designs and implements liquid filling systems that seamlessly integrate with your production lines for optimal performance.

- Turn-Key Project Management: We manage every phase of your project, from initial planning and design to installation and commissioning, ensuring a smooth and stress-free process.

- Start-Up and Commissioning Services: Our field technicians provide on-site assistance to ensure your equipment is operational and performing to specification.

- Troubleshooting and Upgrades: Address challenges quickly and efficiently with our expert technical support, or enhance your system’s capabilities with our upgrade services.

- Rebuilding and Maintenance: Restore and extend the life of your liquid filling equipment with our rebuilding solutions, designed to keep your machinery in peak condition.

Global Reach, Tailored Expertise

With clients around the world, Laub\Hunt brings a unique combination of global experience and industry-specific expertise to every project. Our solutions are customized to fit the needs of businesses across various sectors, ensuring you receive the right support no matter your location or production scale.

Standing Behind Every Solution

At Laub\Hunt, quality and customer satisfaction are at the heart of everything we do. We take pride in offering dependable solutions and standing behind our products and services. This unwavering commitment to excellence has made us a leader in the liquid filling equipment industry, trusted by businesses globally.

Let LAUB\HUNT Elevate Your Operations

Choose LAUB\HUNT for comprehensive engineering services that drive efficiency and innovation in liquid filling equipment solutions. From concept to completion, our team ensures your production line operates seamlessly.

Transform your liquid filling operations with Laub\Hunt—where expertise meets innovation.