Innovations in Bottle Filling Equipment: What's New in 2025?

Innovations in Bottle Filling Equipment: What's New in 2025?

The landscape of bottle filling equipment continues to evolve, with new technologies and innovations shaping the way industries operate. In 2025, the focus remains on enhancing efficiency, sustainability, and precision. At Laub/Hunt, we stay ahead of the curve, offering advanced bottle filling solutions that meet the demands of modern production lines.

Enhanced Automation for Seamless Production

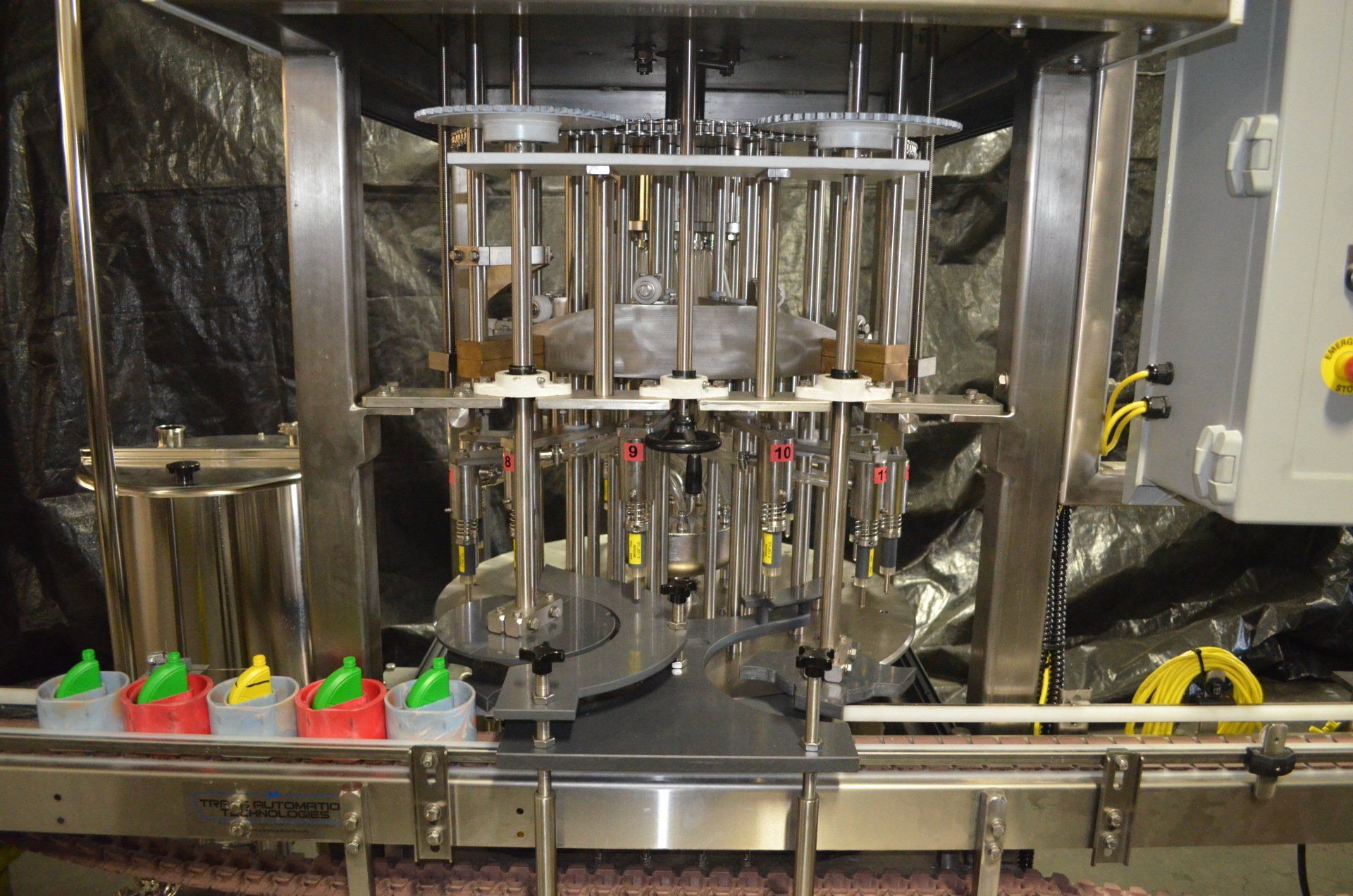

Automation remains a cornerstone of innovation in bottle filling equipment. The latest systems integrate smarter controls and intuitive interfaces, making them easier to operate while increasing throughput. These advanced machines adapt quickly to different bottle sizes and liquid types, offering flexibility without compromising speed or accuracy.

Sustainability at the Forefront

As businesses strive to reduce their environmental impact, bottle filling equipment has risen to the challenge. New systems are designed with sustainability in mind, incorporating features that minimize waste and optimize energy consumption. From reducing product loss to cutting down on packaging materials, these innovations align with the global push for greener operations.

Precision Redefined

Advancements in filling technology continue to refine accuracy, ensuring every container is filled to exact specifications. Whether handling thick syrups, delicate essential oils, or carbonated beverages, precision filling equipment eliminates inconsistencies, protecting your product and reputation.

User-Centric Designs

Ergonomic and user-friendly designs are reshaping the industry. New equipment prioritizes easy maintenance, quick changeovers, and streamlined workflows, reducing downtime and operational headaches. At Laub/Hunt, we understand the value of keeping your production line running smoothly.

Custom Solutions for Unique Needs

Every business has unique challenges, and 2025’s innovations address this diversity with customizable solutions. Tailored filling equipment allows businesses to maintain efficiency while meeting specific production goals. At Laub/Hunt, we work closely with clients to ensure our systems fit seamlessly into their processes.

Stay Ahead with Laub/Hunt

The future of bottle filling is here, and Laub/Hunt is ready to help you take advantage of these advancements. Whether you’re upgrading your existing equipment or starting a new production line, our innovative solutions are designed to elevate your operations.

Let’s Innovate Together

Contact Laub/Hunt today to learn more about our cutting-edge bottle filling equipment. Explore how we can help your business thrive with the latest innovations for a more efficient, sustainable, and successful future.