Types of Bottling Systems: Choosing the Right Solution for Your Production Line

Selecting the appropriate bottle filler is crucial for optimizing your production line's efficiency and ensuring product quality. At

Laub/Hunt, we offer four distinct types of bottle fillers, each designed to meet specific production needs.

Rotary Mag-Flow Filler

Our Rotary Mag-Flow Filler utilizes electromagnetic flow meter technology to achieve precise and accurate filling. This system is ideal for the beverage industry, ensuring consistent fill volumes for products like juices, water, and other non-carbonated drinks. The rotary design enables high-speed operations, making it suitable for large-scale production lines.

Key Features:

- High Precision: Magnetic flow meters provide accurate measurement of liquid flow rates.

- High-Speed Operation: Rotary mechanism allows for efficient filling at high speeds.

- Versatility: Suitable for a wide range of liquid products.

Pressure Metering Filler

Designed for high-viscosity and semi-liquid products, the Pressure Metering Filler employs a positive displacement pump to maintain consistent pressure, ensuring uniform fills. This filler is perfect for products like sauces, creams, and other thick substances. Its sanitary design includes stainless steel construction and Clean-In-Place (CIP) systems, facilitating easy cleaning and maintenance.

Key Features:

- Accurate Filling: Achieves fill accuracies of +/- 0.5%.

- Sanitary Design: Stainless steel construction suitable for food and cosmetic products.

- Versatility: Handles a wide range of high-viscosity products.

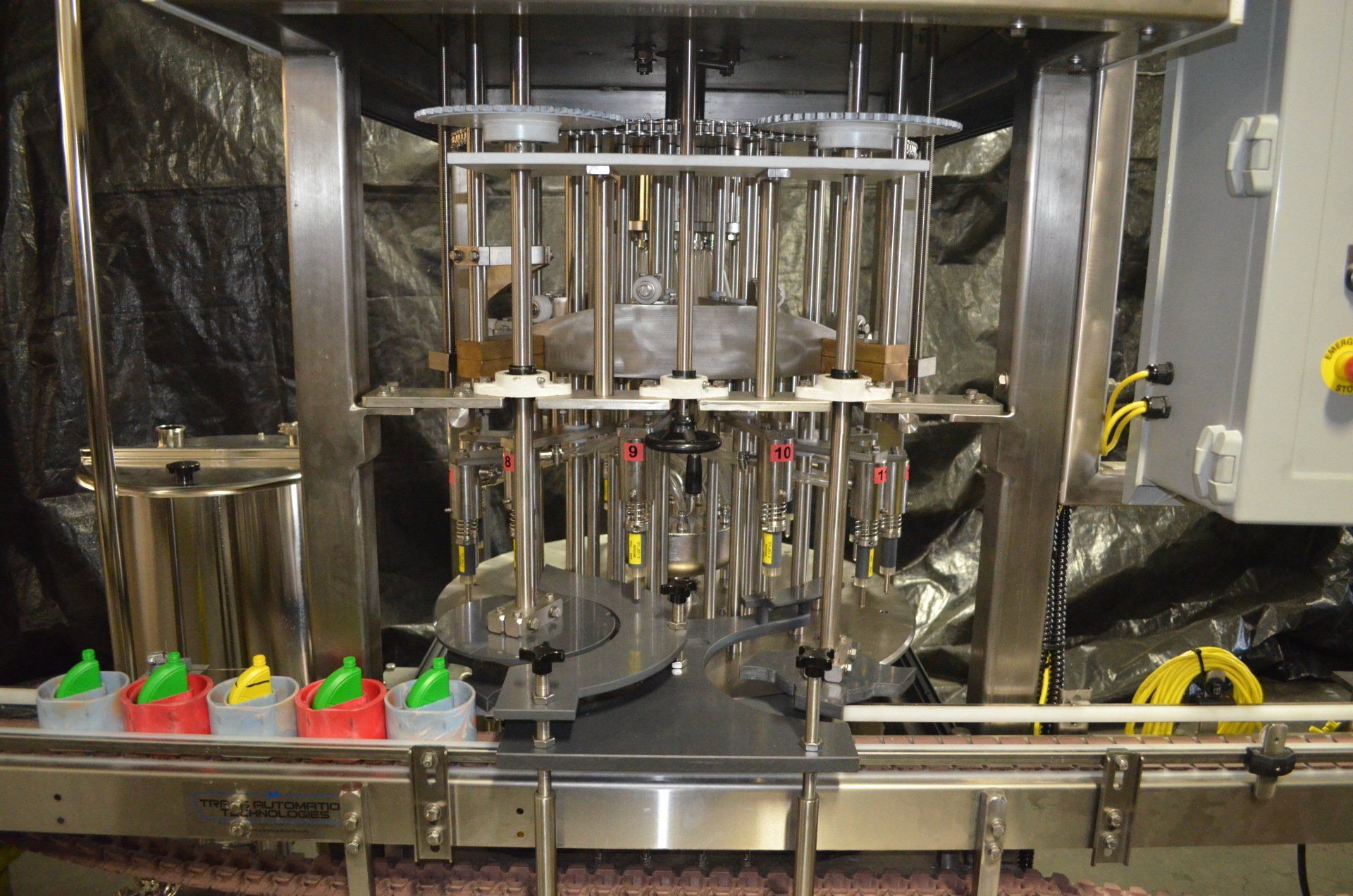

Rotary Volumetric Filler

The Rotary Volumetric Filler operates on a positive displacement principle, ensuring each container receives an exact volume of product. This system is beneficial for products where precise volume is critical, such as in pharmaceuticals or specialty chemicals. The enclosed design prevents air from entering the system, maintaining product integrity and reducing oxidation.l

Key Features:

- Precision: Delivers exact volumes for each fill.

- Enclosed System: Prevents contamination and maintains product quality.

- Adaptability: Suitable for various liquid viscosities.

Rotary Liquid Filler

Our Rotary Liquid Filler offers multiple filling methods, including gravity, pressure, and vacuum systems, to accommodate different product characteristics. This flexibility makes it ideal for a diverse range of products, from thin liquids like water to more viscous substances. The machine's design ensures high-speed filling with fill accuracy of +/- 1/16 inch, enhancing both efficiency and precision.

Key Features:

- Multiple Filling Methods: Customizable to product-specific requirements.

- High-Speed Filling: Capable of speeds up to 1,000 containers per minute.

- Precision: Ensures consistent fill levels across all containers.

Choosing the right bottle filler depends on factors such as product viscosity, desired fill speed, and specific industry requirements. At Laub/Hunt, we are committed to providing tailored solutions that meet your unique production needs.

Explore Our Filling Solutions

Visit our Fillers page to learn more about each of our bottle fillers. Our team of experts is ready to assist you in selecting the perfect equipment to enhance your production line's efficiency and product quality.

Contact Us Today

For personalized assistance and to request a quote, contact us. Let Laub/Hunt be your partner in achieving optimal filling solutions for your business.