Maximizing ROI with Advanced Bottle Filling Machinery

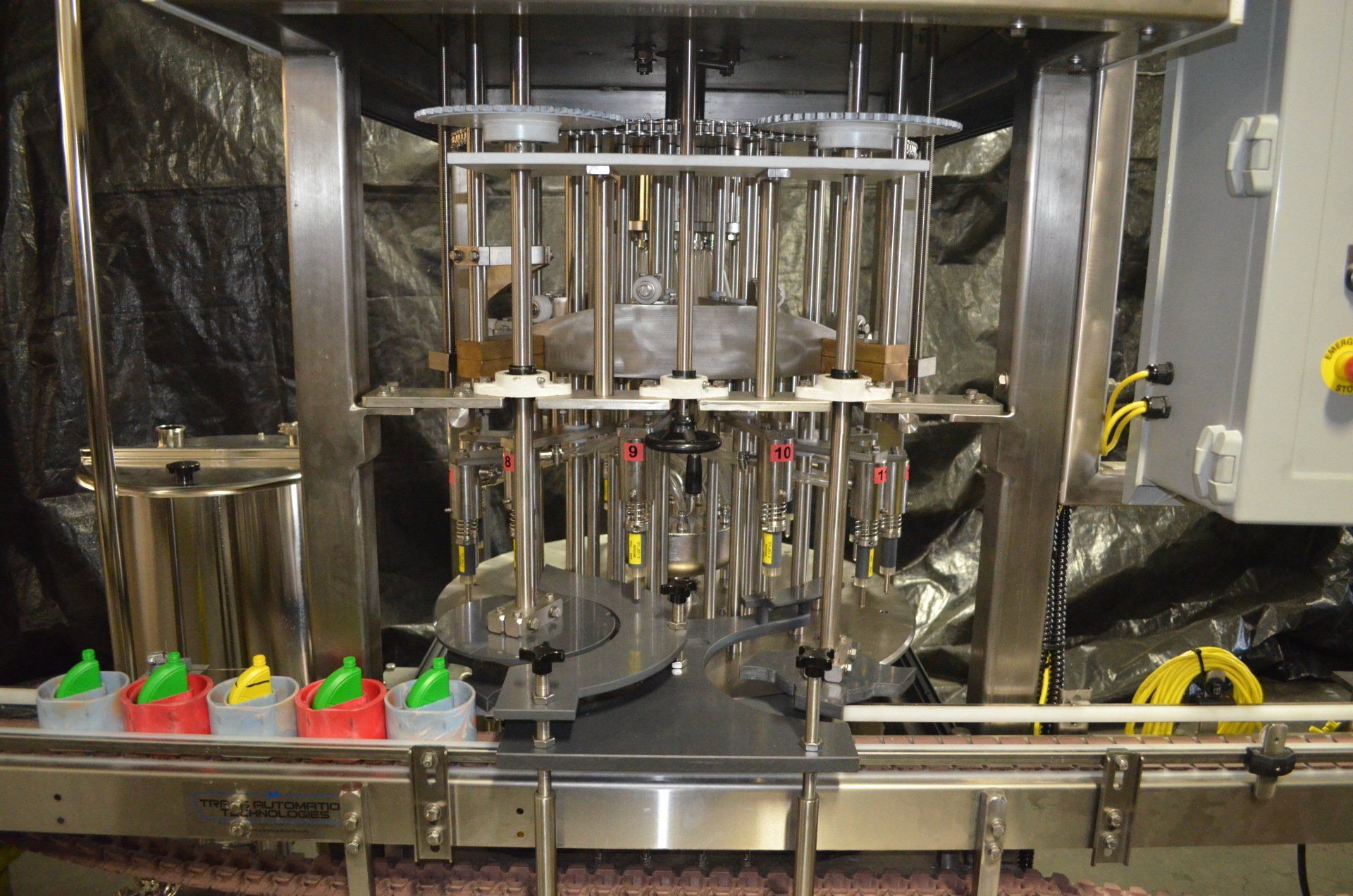

In the beverage, pharmaceutical, and personal care industries, optimizing your production line for efficiency and profitability is critical. Investing in advanced bottle filling machinery can significantly improve throughput, reduce product waste, and lower operational costs, leading to a strong return on investment (ROI). Whether you're a small business scaling up production or a large manufacturer looking to enhance efficiency, choosing the right bottle filling machine can make all the difference.

The ROI of Upgrading to Advanced Bottle Filling Machines

1. Increased Production Speed

Modern bottle filling machines can process thousands of bottles per hour, far outpacing manual or semi-automated systems. Faster production speeds mean higher output, which translates to greater revenue potential.

2. Reduced Product Waste

Precision is key in liquid filling. Advanced machinery from Laub/Hunt ensures accurate fill levels, minimizing product loss due to spillage or overfilling. Over time, these savings contribute to a higher ROI.

3. Lower Labor Costs

Automation reduces the need for manual labor, allowing businesses to operate efficiently with a smaller workforce. This cost reduction improves profit margins and allows employees to focus on quality control and other value-added tasks.

4. Versatility and Adaptability

Investing in a machine that can handle different bottle sizes, cap types, and viscosities can future-proof your production line. Laub/Hunt offers versatile bottle filling solutions designed to adapt to evolving market demands.

5. Enhanced Product Quality and Consistency

Uniform fill levels and reduced contamination risks contribute to improved product quality, which enhances brand reputation and customer satisfaction.

Choosing the Right Bottle Filling Machinery

When selecting the best bottle filling equipment, consider the following factors:

Type of Liquid: Viscosity, foaming properties, and particulate content determine the type of filler needed.

Production Volume: High-speed automated fillers are ideal for large-scale operations, while smaller businesses may benefit from semi-automatic solutions.

Container Type and Size: Machines should accommodate the range of bottles used in your product line.

Regulatory Compliance: Ensure your equipment meets industry standards, particularly in the food, beverage, and pharmaceutical industries.

Explore Laub/Hunt's Bottle Filling Machines to find the right fit for your production needs.

Optimize Your Production Today

Upgrading to an advanced bottle filling machine is a strategic investment that maximizes efficiency, reduces costs, and ensures consistent product quality. At Laub/Hunt, we specialize in providing high-performance filling solutions tailored to your industry's specific requirements.

Ready to enhance your bottling process and boost your ROI? Contact Laub/Hunt today to discuss your production needs and discover the best solution for your business.