Information about Mag Flow (Magnetic Flow) Rotary Fillers

Information about Mag Flow (Magnetic Flow) Rotary Fillers

Mag Flow (Magnetic Flow) Rotary Fillers are a type of filling machine commonly used in the beverage industry for filling liquid products into bottles or containers. These fillers utilize magnetic flow meter technology to achieve precise and accurate filling. Here's an overview of Mag Flow Rotary Fillers:

Magnetic Flow Meter Technology:

Principle: Mag Flow Fillers rely on the principles of electromagnetic flow measurement. When a conductive liquid flows through a magnetic field, it induces a voltage that is directly proportional to the flow rate.

Accuracy: This technology provides high accuracy in measuring the flow rate of liquids, making it suitable for applications where precise filling volumes are crucial.

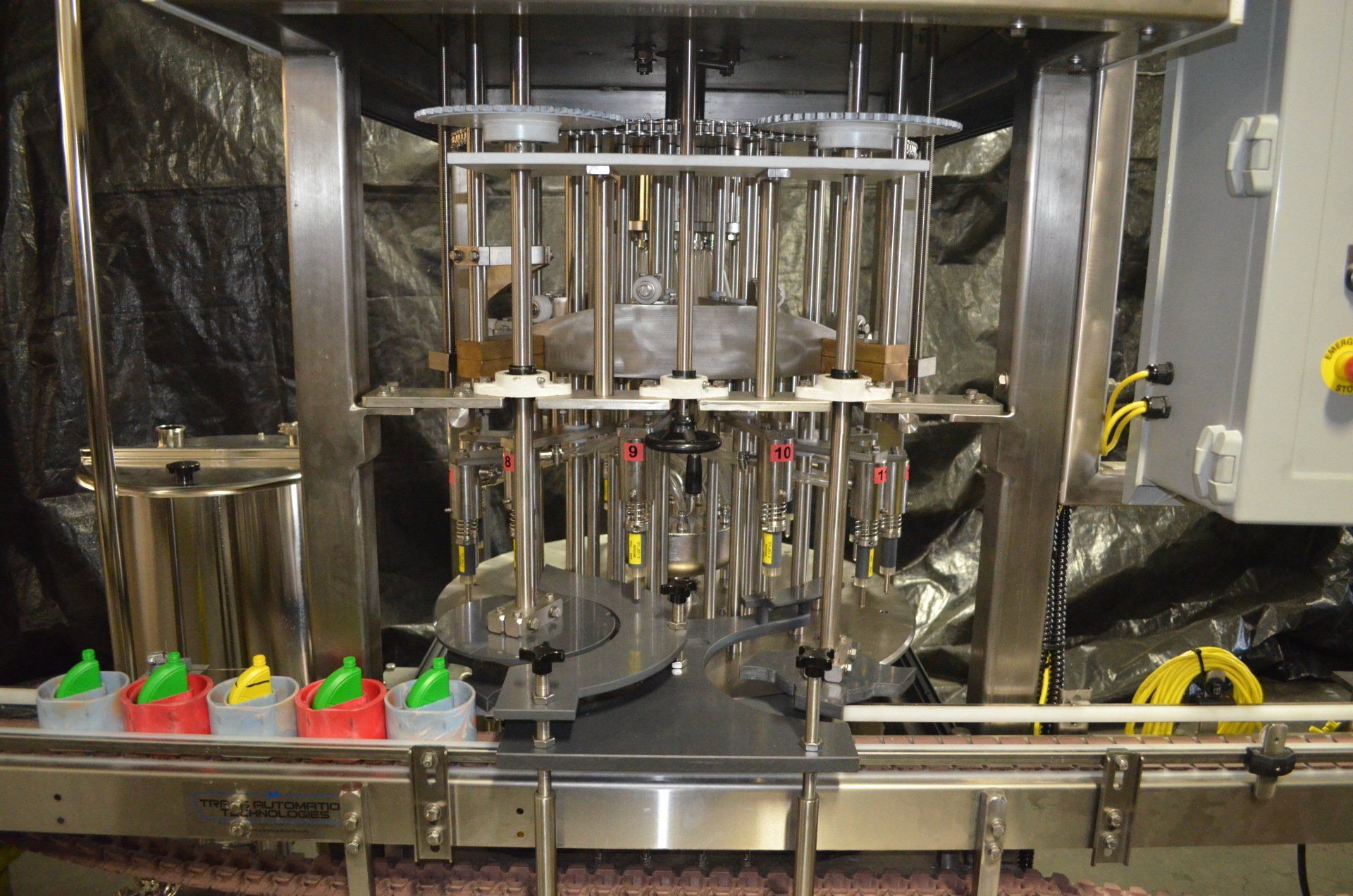

Rotary Filling Mechanism:

Design: Mag Flow Rotary Fillers are equipped with a rotary mechanism that allows bottles to move through the filling station in a circular or rotary fashion.

Advantages: The rotary design enables high-speed filling operations, making these fillers suitable for high-throughput production lines.

Bottle Handling System:

Conveyor System: Bottles are typically transported on a conveyor system that moves them through different stations, including filling and capping.

Indexing: The rotary mechanism indexes the bottles through each station, ensuring that they are precisely positioned for filling.

Filling Process:

Precision Filling: Mag Flow technology ensures accurate and repeatable filling volumes. The flow meter measures the liquid flow rate, and the filling nozzles dispense the exact amount of product into each bottle.

Clean Filling: These fillers are suitable for filling a variety of liquid products, including beverages, and are often used in applications where cleanliness and hygiene are essential.

Capping Station:

Integration: Mag Flow Rotary Fillers are often part of a larger packaging line that includes a capping station. After filling, bottles move to the capping station where caps are applied and secured.

Control System:

Automation: These fillers are typically equipped with an automated control system that oversees the filling process. This system ensures that the correct fill volume is maintained, and it may interface with a central control system for the entire packaging line.

Cleaning and Maintenance:

CIP (Clean-in-Place): Mag Flow Rotary Fillers are designed to facilitate cleaning between product changeovers. Some models may have integrated Clean-in-Place systems to streamline the cleaning process.

Versatility:

Product Range: Mag Flow Rotary Fillers are versatile and can handle a wide range of liquid products, including carbonated and non-carbonated beverages, juices, water, and more.

These fillers are a popular choice in industries where precise and high-speed filling is required, and the use of magnetic flow meter technology enhances their accuracy and reliability in achieving consistent fill volumes.

Contact us for more information.